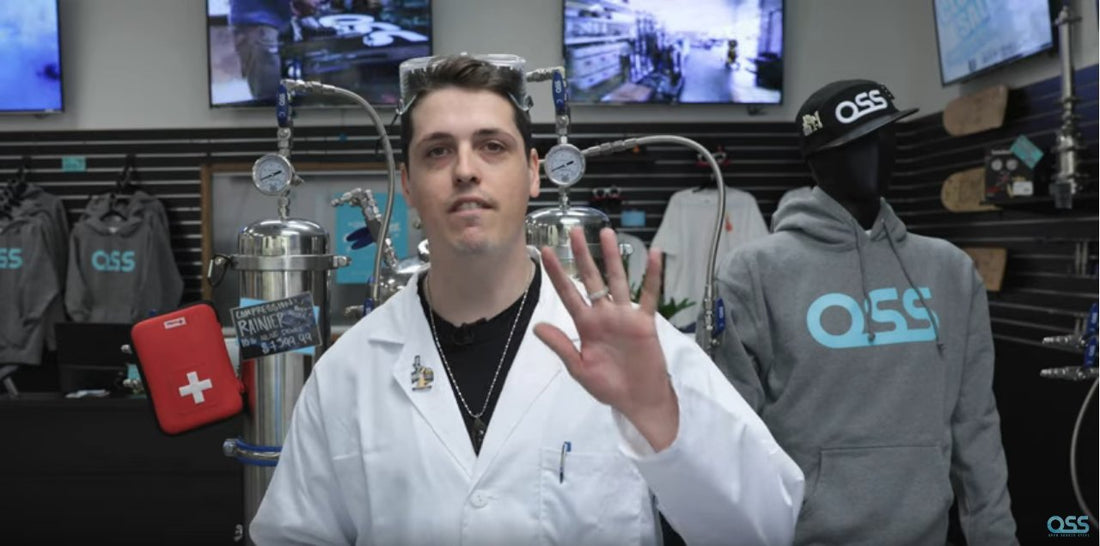

5 Corners Not To Cut…. For Beginners

Ultimate Rule #1: Safety First! Always Pressure & Vacuum Test prior to any extraction

- Clean Solvent / Distilling Gas

- Source 99.95+% Solvents from reliable sources, don’t use Blue Rhino or Gas Station propane!

- Distill all solvents prior to use to remove any and all “mystery oil” or lubricants from production.

- Store in sanitary stainless steel tank, do not use Carbon steel it can rust!

- Cold Solvent / Frozen Material = Better color/terps

- Colder the better!

- Coagulate Fats, Impurities and keep moisture frozen < 32f!

- Cons, Reduces solvent pressure and will require pressure assist using Nitrogen or Warm Butane tank!

- Molecular Sieve 3A, 4A, Indicating

- 3A Molecular Sieve is primarily for removing moisture from liquefied and gaseous materials.

- Has a pore size of 3A or 3 angstrom. Any molecule larger than 3A will not be able to be adsorbed.

- 3A Molecular Sieve can be regenerated and reused. To regenerate the sieve you need to remove the adsorbed moisture and other materials. To regenerate 3A Molecular Sieve heat to 250ƒ.

- Keep 3A Molecular Sieve in an airtight container until ready for use to avoid unintended moisture adsorption.

- Pump Maintenance

- Service and Regular Cleaning

- Check for piston blowby / Crankcase leaks

- Backup Pump

- Organization / Feng Shui

- Adequate Space for working

- Prep Space

- Tools

- Cleaning Supplies

- Extra Material Spools / Socks

- Garbage

Try to make your life easier, not harder!